True Velocity: Re-Defining The ‘Metallic’ Cartridge

Don’t get the impression that the material, which must withstand very high pressures, was easily created. It’s not just “plastic.”

Although “technology” may be viewed as repugnant by some—especially among older adults—the associated advancements aren’t necessarily unfavorable. As an example, until the advent of the self-contained, all-metallic cartridge in the 19th century, the components required to discharge a firearm—ignition source, powder/propellant and projectile(s), among other things—were, for the most part (excluding integrated paper cartridges), carried separately and added sequentially. These actions were often performed under the duress of a hunt or during combat, which further complicated the procedure. Self-contained cartridges eliminated many unnecessary steps. Reloading a firearm was greatly sped up. Fewer components were lost or ruined. The list of benefits goes on and on.

But while many aspects of our world—phones, airplanes and automobiles, for example—have progressed greatly over the past century or so, ammunition has seen minimal development. Sure, there are newer, cleaner-burning, high-energy propellants, as well as bullets that can do virtually anything asked of them. Need one that expands at 1,000 yards with boring consistency yet will maintain its integrity at closer ranges? No problem. Want a projectile that creates multiple wound channels for rapid hemorrhaging, even at subsonic velocities? Done. But the holder of the key components, the cartridge case, differs little. That’s now changing, thanks in part to True Velocity Ammunition (tvammo.com).

Background

“Most people who visit True Velocity for the first time are unaware that the company has actually been in existence, in some form or fashion, for more than a decade,” said Pat Hogan, chief marketing and sales officer for True Velocity Ammunition, LLC. “When our founder and chairman, Kevin Boscamp, was first approached with this opportunity about 15 years ago, the first action he took was to underwrite the market in an effort to understand the size and scope of the opportunity. He realized four critical drivers for taking our lightweight ammunition and advanced manufacturing technology to market: lack of innovation; lack of intellectual property around lightweight ammunition; the size of the market (enormous global market and current unprecedented demand); and timing (military and defense industrial base modernization). So, when you put these four factors on the table, there is a clear business case for taking True Velocity’s product and manufacturing capabilities to the market now. And that’s what we’re in the process of doing, on a global scale.”

Until the competition for the U.S. Army’s Next Generation Squad Weapon (NGSW) program commenced, True Velocity Ammunition wasn’t on the radar of most firearm enthusiasts—but it most certainly was once the company made it to the final round, before being nosed out by another finalist.

Concerning the NGSW program, Hogan said, “To remove our soldiers from that situation of ‘overmatch’ and to create stand-off, the U.S. Army set out to fire a government-proprietary projectile in a 6.8 mm chambering at a high velocity, to achieve superior terminal ballistics and greater effective range. However, the Army also placed an emphasis on reducing the burden on the soldier by minimizing the weight of the ammunition and weapon system.”

“True Velocity ultimately provided a solution that met or exceeded the performance requirements,” Hogan said. “Our 6.8 True Velocity Composite Munition (TVCM) cartridge exceeded target velocities with normal, safe operating pressures, while simultaneously offering more than a 25 percent weight reduction over traditional, brass-cased 7.62×51 mm cartridges.” (A future civilian version of the cartridge will be labeled 6.8 TVC.) So, how did they achieve the weight reduction? It all begins by breaking with tradition.

A Better Case-Making Material?

Outside of steel and aluminum, or some combination thereof, which are chiefly employed in economy fodder—this is changing, too—brass is still the principal case-making material. Why? Frankly, it’s still among the best choices for the task. Brass is malleable, capable of withstanding high pressures, can apply neck tension and has excellent spring-back, so it can expand to fill the chamber during firing yet be easily extracted. It’s also more resistant to corrosion than many metals and, in most cases, can be reloaded multiple times, thereby saving money.

But with the good comes the bad. Brass is heavy. Although of little concern to most hunters and riflemen, such a concern is important for those who have to carry ammunition in quantity, such as a soldier, or ship it. Heft comes at a cost, both physically and monetarily. Moreover, the average shooter doesn’t reload, and the soldier in theater isn’t scrounging for brass, so the high cost associated with a material that can be re-used is, frankly, a waste. True Velocity found the solution.

“Despite the fact that the U.S. [Department of Defense] has some form of requirement for lightweight ammo going back more than 40 years, hardly any intellectual property had been established in the lightweight-ammo space when True Velocity began,” Hogan said. “We have since changed that dynamic, having established more than 350 patents either issued or pending around our product. We anticipate extending that portfolio by perhaps several hundred more patents focused on our manufacturing technology.”

To reduce weight, the company’s ammunition employs an innovative, two-piece composite case in which the base of the case is molded around a steel insert that secures the primer in place and has an integral rim. The nose of the case is molded separately. “The components are then joined using a proprietary process to form the complete cartridge case,” Hogan explained.

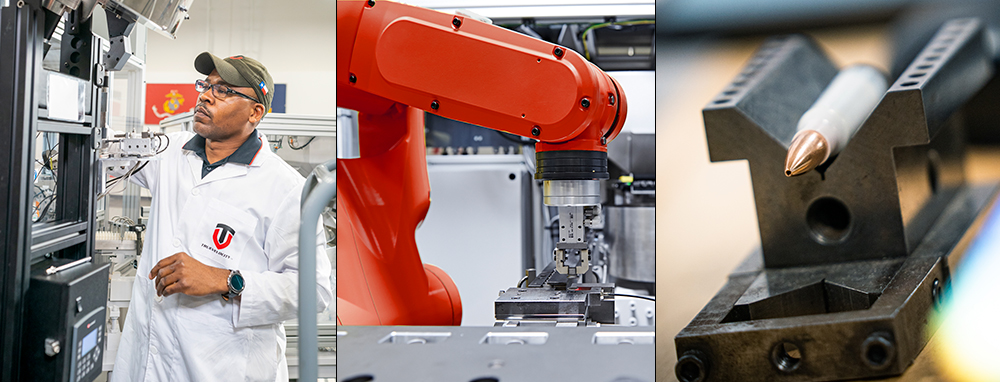

Don’t get the impression that the material, which must withstand very high pressures, was easily created. It’s not just “plastic.” “There is far more involved in producing a composite case material that can withstand these types of substantial pressures and temperatures than selecting the ‘right plastic,’” explained Hogan. “True Velocity’s team of engineers, material scientists and molding experts has spent an inordinate amount of time and significant resources to determine the optimal polymer materials, additive packages and processing parameters that will ensure full functionality under the stress of 50,000-plus p.s.i. across a broad range of environmental conditions.”

When holding a True Velocity case, you’ll immediately note the smoothness of its exterior. The lubricity is obvious; it feels as though the surface is oily. This isn’t by happenstance. According to Hogan, “Our cartridge case has to exhibit a high degree of lubricity and ductility while simultaneously offering enough rigidity to stand up to the rigors of automatic fire and violent extraction. While we will stop short of discussing the details of our formula and process, it’s safe to say that the development is highly complex.”

True Velocity’s use of composite cases cuts cartridge weight, however, there are other less-obvious benefits, too. Shotgunners (and those who reload shotshells) understand that the internal geometry of shotshells can—and does—vary greatly. Internal changes affect the type and amount of propellant used and resultant pressures, among other things. The same applies to True Velocity’s composite cases; they can be tailored internally for specific traits.

“With a brass case, the internal geometry is essentially dictated by the external geometry, and there’s little you can do to manipulate the internal dimensions of the case,” Hogan said. “That’s primarily due to the method of manufacture—progressive dies pounding a piece of metal into an intended shape. When you’re molding the cartridge case, as is True Velocity, you can do almost anything you want on the inside. We can increase or decrease case-wall thickness to manipulate case capacity for something like a subsonic application. We can alter the internal shoulder angle so that it does not match the external shoulder angle, allowing us to influence gas flow. And we can do things [to] alter the configuration of the bottom of the case cup to allow for a more efficient and complete powder burn. Ultimately, our ability to manipulate the interior profile of the cartridge case lifts the proverbial ceiling off what was thought to be possible with internal ballistics.”

The cases are uniform, too, which increases accuracy. “Our molding capabilities allow for significantly improved dimension consistency—and, specifically, dimensional concentricity and Total Indicator Reading,” Hogan said.

“If every case is effectively identical to the case produced before it and the case produced after it, then they tend to behave the same upon firing.” Weighing five random, fired True Velocity .308 Win. cases on the scale of an RCBS ChargeMaster Lite showed a high-low variation of 0.2 grains; three weighed 81.4 grains, while one each were 81.2 grains and 81.3 grains. That’s extraordinary consistency!

For all the benefits that polymer has as a case-making material, there is a disadvantage that True Velocity had to address. On “metallic” cartridges, the projectile must be secured in place, or tensioned, to prevent migration; a mechanical crimp is the usual means. Problem is that polymer cannot do so. “We use a proprietary process to establish neck tension, and it can be adjusted to meet specific bullet-pull requirements or optimize performance,” Hogan said. What is done? From the exterior of a .308 Win. round loaded with a 165-grain Nosler AccuBond, there are five red/pinkish lines of what appears to be an adhesive between the bullet and interior of the case neck. Once “broken,” the bullet could be extracted and some of the remnants of the material were on the bullet, too.

The Complete Package

Beyond the innovative case, True Velocity seeks other up-to-date components—such as propellants—for its ammunition; however, the case itself negates many of the issues other companies face. “[For instance], our ability to reduce—almost eliminate—muzzle flash is influenced by more factors than the type of propellant being used,” Hogan said. “Muzzle flash is the indication of an inefficient ballistic event. That visual signature is, basically, unburned granules of powder igniting as they exit the barrel of a weapon. Our ability to manipulate case geometry allows us to ensure a more complete and more efficient powder burn, as evidenced by the fact that we can use 8 to 10 percent less gunpowder than a comparable brass cartridge case, yet still achieve the same muzzle velocity. If all of the gunpowder combusts inside the cartridge case, then not only are we harnessing more energy to propel the projectile, but we are also sending less unburned powder down the barrel and, thus, producing far less muzzle flash.”

Concerning the decrease in propellant usage, that’ll reduce felt, or perceived, recoil as well; propellant powder charge weight, along with bullet heft and muzzle velocity, are the determinants of recoil.

True Velocity reports that its ammunition is capable of producing single-digit standard deviations “typically for 10 shots.” Is this a foolhardy claim? No. Not only are the cases absolutely uniform dimensionally, Hogan remarked that “our powder-drop technology on our manufacturing lines employs best-practices from the pharmaceutical industry to ensure that our powder-drop standard deviation is held to the hundredth of a grain.” Yes, you read that correctly. Plus, very tight tolerances are held on neck tension, resulting in minute variations in bullet-pull from round to round.

Currently, True Velocity is offering consumers only .308 Win. ammunition. Fortunately, the company selected some of the best bullets available for the cartridge. Customers can select from the Nosler 165-grain AccuBond, Nosler Custom Competition 168-grain HPBT and Sierra MatchKing 168-grain HPBT. Sierra’s 175-grain MatchKing HPBT will be available soon. Other chamberings should follow shortly thereafter. “We expect to launch commercial sales of our .223 Rem. round in Q4 2022 or Q1 2023, and we’ll roll out our 6.5 mm Creedmoor sometime in the first half of 2023,” Hogan said. “And we are working with a growing list of commercial rifle manufacturers the likes of Lewis Machine & Tool, Rock River Arms and Daniel Defense to chamber rifles for our 6.8 TVC round, which is the civilian version of the cartridge we developed for the Next Generation Squad Weapon program. That cartridge became the first polymer-cased cartridge to be certified by the Sporting Arms and Ammunition Manufacturers’ Institute (SAAMI) in January 2022.”

Testing

True Velocity ammunition represents a significant departure from the norm. But how does that translate on the range? That’s what I sought to determine through extensive testing, which occurred over multiple sessions.

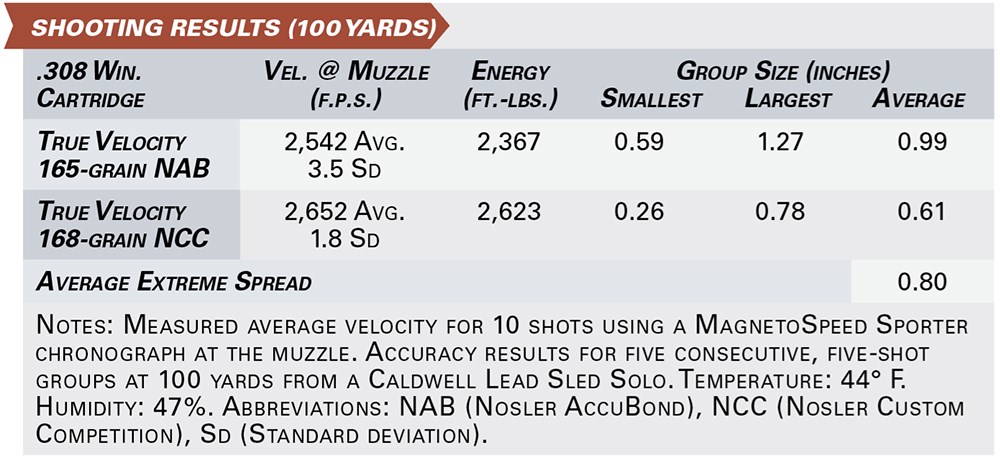

To extract the utmost performance from the two loads available at the time of testing—the Nosler 165-grain AccuBond and Custom Competition 168-grain HPBT—I secured a 20″-barreled Springfield Armory Model 2020 Waypoint with adjustable comb and carbon-fiber barrel topped with a Leupold Mark 3HD 4-12X 40 mm scope. Following American Rifleman protocol, accuracy testing was conducted at 100 yards—in this case, from a weighted Caldwell Lead Sled Solo—and five consecutive, five-shot groups were fired with each load.

First up was Custom Competition. Clearly the rifle’s match, of the five groups, from center to center, the smallest (and first) measured a scant 0.26″, while the largest went 0.78″. The average came to 0.61″. The AccuBond load posted an average of 0.99″. Its tightest five-shot cluster was 0.59″, while the largest, due to shooter error, jumped to 1.27″.

There’s no doubt that, in a premium rifle, True Velocity’s ammunition can deliver fine accuracy, but I was skeptical that it’d meet the company’s touted, single-digit standard deviation (Sd). To test this, I fitted the Model 2020 Waypoint with a barrel-mounted MagnetoSpeed Sporter chronograph and proceeded to fire 10-shot strings with each load. According to True Velocity’s website, the Custom Competition 168-grain HPBT load attains 2,650 f.p.s. The MagnetoSpeed Sporter revealed an average of 2,652 f.p.s. with an Sd of 1.8. Think about that for a moment. That’s almost unheard of, let alone from factory ammunition. The 165-grain AccuBond, which has an identical published velocity, shed some of its speed; its average was 2,542 f.p.s., with an Sd of 3.5. Again, that’s remarkable consistency for a 10-shot string. It’s little wonder why the test rifle shot so well.

During testing, there were no issues encountered feeding, firing, extracting or ejecting, and the steel head made cleanup with a magnet simple and fast. Also, none of the whitish cases could hide in the long grass alongside the bench.

According to True Velocity, its ammunition is 30 percent lighter than traditional brass-cased ammunition. Given its use of a composite case, that’s easy to see. To illustrate the difference, on the previously mentioned RCBS ChargeMaster Lite scale, I weighed four random, de-primed, once-fired .308 cases. Whereas the True Velocity case weighed 76.1 grains, those from Lapua, SIG Sauer and Remington were 174.0 grains, 169.5 grains and 162.2 grains, respectively. That’s a significant savings! Between the heaviest (Lapua) and True Velocity, there was a 97.9-grain difference per case, or 1,958 grains per 20. Converted to ounces, that’s about 4.48 ozs.—or slightly more than a quarter of a pound—per box. And, that doesn’t reflect how lighter propellant charges in True Velocity cases can achieve equivalent velocities. Truly, True Velocity Ammunition is different, but in a good way.

As one might expect, technology and premium product comes at a price. True Velocity’s composite-cased ammunition isn’t inexpensive; a 20-round box of .308 Win. costs $69. While that price will deter plinking, those who want (or need) absolute consistency or are looking for ways to cut ounces (or both) will find True Velocity’s product to be attractive. Regardless, the company has changed the landscape of centerfire “metallic” cartridges forever.